1. Design and additive forming of light weight high strength superalloy;

2. Preparation of wear-resistant, corrosion-resistant and high-temperature oxidation-resistant coatings by laser cladding;

3. Controllable preparation of metal composite porous materials and its application in energy conservation and emission reduction

1. “National Natural Science Foundation of China”, “Mechanism of interaction between phase transformation and pore formation of novel high Nb-TiAl-based porous nanocomposite”, NO. 52101070, 300000 RMB, 2022-2024”.

2. “Ministry of Science and Technology”, “Key Technologies for High Quality TiAl Alloy Powder Preparation and 3D Printing”, NO. 2021YFB3700500, 16500000 RMB, 2021-2025”.

3. “Fundamental Research Funds for the Central Universities”, “Fracture mechanism of Ni-based alloys coating fabricated on low alloy steel by ultra-high-speed laser cladding”, NO. FRF-TP-19-080A1, 100000 RMB, 2019-2021.

4. “China Postdoctoral Science Foundation”, “Failure mechanism of TiAl-based porous materials in extreme/multi-factor coupling environment”, No. 2019M660452, 80000 RMB, 2019-2020.

5. “Science and Technology Department of Zhejiang Province, Leading Goose Project”, “Research on Manufacturing Technology and Equipment of Laser Composite Surface with High Wear Resistance and Corrosion Protection for Nuclear Power Units”, No. 2024C01196, 2600000 RMB, 2024-2026.

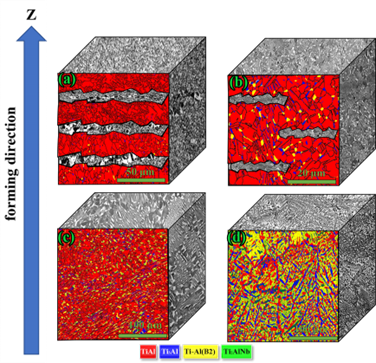

Significant achievements have been made in preparing Ti2AlNb/Ti-48Al-2Cr-2Nb composites using an EBM-forming method. The current Ti-48Al-2Cr-2Nb alloy experience compositional loss when operating above 650°C, limiting their service temperature to that threshold and preventing them from performing effectively at higher temperatures. To address this issue, a dense Ti2AlNb/Ti-48Al-2Cr-2Nb composite material was fabricated using a mixture of Ti2AlNb and Ti-48Al-2Cr-2Nb powders, along with process optimisation. Additionally, the evolution of microstructure, phase composition, and phase distribution of the composite material was studied, as well as the mechanisms by which microstructural features and phase distribution influence its mechanical properties. The research findings indicate that the optimal process for samples with different Ti2AlNb content achieved a density exceeding 98%. As the amount of Ti2AlNb increased, the microstructure transitioned from fine equiaxed grains to coarse dendrites, and the phase composition shifted from a dominance of the γ phase to a predominance of the B2 phase. The higher levels of α2 phase and O phase in the composite material increased its room-temperature tensile strength by 11% and high-temperature tensile strength by 32%, while the elevated B2 phase content resulted in higher yield strength. Grain size, microstructural uniformity, Nb and O phase content, along with the activity of the B2 phase at high temperatures, contributed to a creep behaviour characterised by resistance to deformation failure, thereby enhancing the material's damage tolerance.

Fig 1. Microstructure and phase composition and distribution of samples with different doping levels of Ti2AlNb: (a) none doping; (b) 10% Ti2AlNb doping; (c) 20% Ti2AlNb doping; (d) 30% Ti2AlNb doping

Fig 2. Display of formed workpieces in relevant application cases

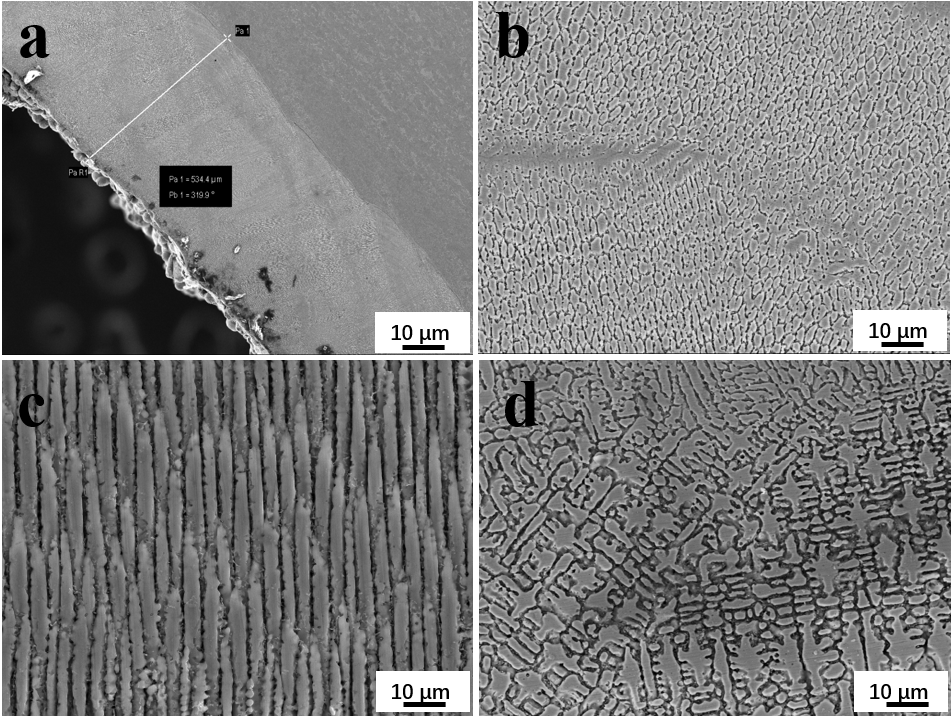

In this work, ultra-low dilution rate Inconel 625 coatings with a thickness of approximately 534.4 μm were prepared by high-speed laser cladding technique on the Q245R steel. The XRD and TEM results shown that the Inconel 625 coatings are mainly composed of the Nb and Mo-enriched laves phase with hexagonal close-packed (HCP) structure and the γ-Ni phase with face-centered-cubic (FCC) structure. The cellular crystal, column crystal and equiaxed dendritic crystal were observed in the bottom, middle and top of the Inconel 625 coatings from SEM results, respectively, as shown in Fig. 3. The wear resistance and corrosion resistance of Q245R steel are significantly improved by high-speed laser cladding Inconel 625 coatings. In addition, the low dilution rate is beneficial for improving the wear and corrosion resistance of high-speed laser cladding Inconel 625 coatings. These findings may provide a method to design the wear and corrosion resistance of coatings on steels surface.

Fig 3. (a) Cross-sectional FESEM images of Inconel 625 coatings; Bottom to top views of Inconel 625 coatings: (b) Bottom zone; (c) Middle zone; (d) Top zone

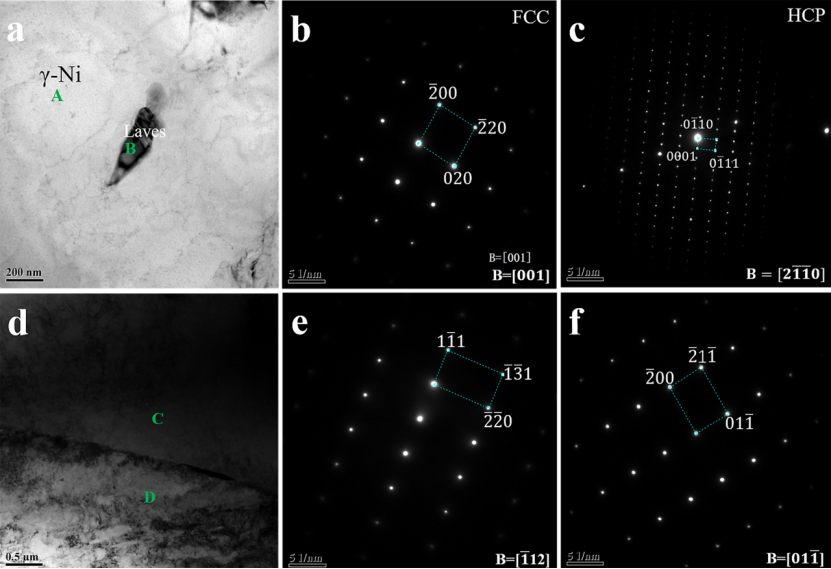

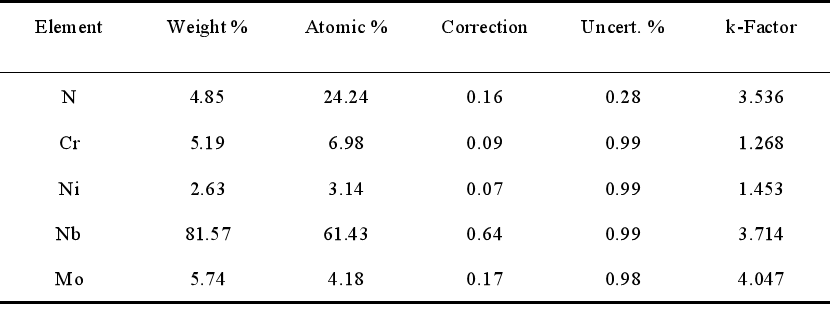

Phase identification for Inconel 625 coating was carried out by using TEM and the results are shown in Fig. 4. Fig. 4a shows the bright field image for an area with coexisting phases. Figs. 4b and 4c display the selected area diffraction patterns for the phase A and phase B in Fig. 4(a), respectively. As shown in Fig. 4b and 4c, the phases A and B shows the characteristics of γ-Ni phase with FCC structure and lavas phase with HCP structure. The chemical composition of lavas phase (phase B) was analyzed by EDS and the results are listed in Table 1. From Table 1, it can be found that the laves phase is rich in Nb and Mo. Fig. 4d shows the bright field image for an area with the interface between Inconel 625 coatings and Q245R steel substrate. Figs. 4e and 4f display the selected area diffraction patterns for the phase C and phase D in Fig. 4d, respectively. As shown in Fig. 4e and 4f, the phases C and D shows the characteristics of α-Fe phase with BCC structure and γ-Ni phase with FCC structure.

Fig 4. TEM image of Inconel 625 coatings (S6): (a) Top view; (b, c) Selected area diffraction patterns for phase A and B corresponding to (a); (d) Bottom to top views; (e, f) Selected area diffraction patterns for phase C and D corresponding to (d)

Table 1. EDS results of lavas phase

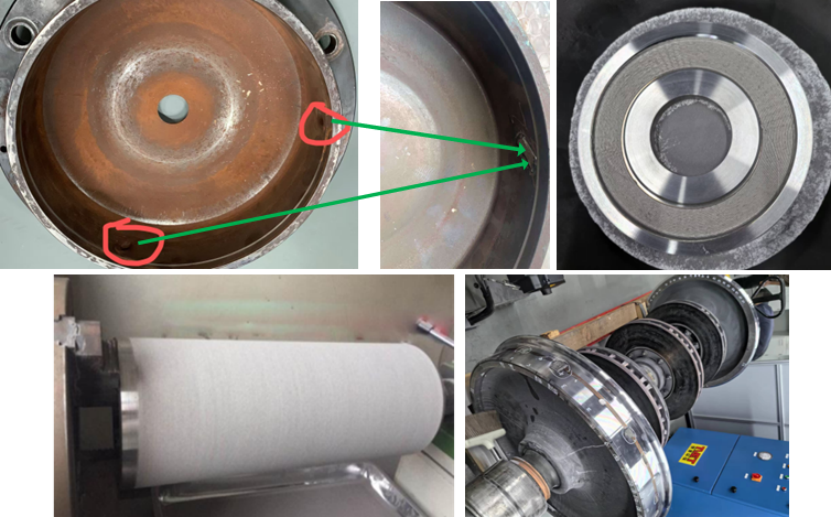

Fig 5. Display of formed workpieces in relevant application cases

1. J Cheng, P Y Yang, Q M Chen, X Long, G Chen, J M Xu, W Y Gui, T Wu, J Hu. Bio-corrosion behaviors and bio-compatibilities of TiNbZrTa and TiNbZrTaMo high entropy alloys. Journal of Materials Research and Technology, 2024, 32: 2268-2278.

2. J C Fu, W Y Gui, J Y Qin, J P Lin, X C Ren, B L Luan. High-speed laser-clad 3533-00 Fe-based cemented carbide coatings on nuclear power valve sealing surface to enhanced wear and corrosion resistance. Surface and Coatings Technology. 2024, 480, 30: 130594.

3. J W Feng, W Y Gui, Q Liu, W Y Bi, X C Ren, Y F Liang, J P Lin, B L Luan. Ti–48Al–2Cr–2Nb alloys prepared by electron beam selective melting additive manufacturing: Microstructural and tensile properties. Journal of Materials Research and Technology, 2023, 26: 9357-9369.

4. Y H Ding, W Y Gui, B X Nie, W Y Bi, C Zhong, Y P Xue, B L Luan. Elimination of elemental segregation by high-speed laser remelting for ultra-high-speed laser cladding Inconel 625 coatings. Journal of Materials Research and Technology, 2023, 24: 4118-4129.

5. K Fu, C Zhong, L Zhang, X M Wang, B X Nie, Y P Xue, W Y Gui, B L Luan. Effect of multiple thermal cycling on the microstructure and microhardness of Inconel 625 by high-speed laser cladding. Journal of Materials Research and Technology, 2023, 24: 1093-1107.

6. B X Nie, Y P Xue, X M Wang, Y H Ding, K Fu, C Zhong, W Y Gui, B L Luan. On the elemental segregation and melt flow behavior of pure copper laser cladding. Surface and Coatings Technology, 2023, 452: 129085.

7. Y H Qu, X M Sun, W Y Gui, R G Li, Z H Nie, Z Y Gao, W Cai, Y Ren, Y D Wang, D Y Cong. Complete and reversible magnetostructural transition driven by low magnetic field in multiferroic NiCoMnIn alloys. Acta Materialia, 2023, 243: 118535.

8. W Y Gui, Y H Qu, Y X Cao, Y Z Zhao, C X Liu, Q Zhou, J Chen, Y H Liu. The effect of Tb substitution for Ni on microstructure, martensitic transformation and cyclic stability of elastocaloric effect in Ni-Mn-Sn magnetic shape memory alloys. Journal of Materials Research and Technology, 2022, 19, 4998-5007.

9. W Y Gui, C Zhong, J Y Gu, Y H Ding, X M Wang, T Wu, Y F Liang, J Y Qin, Y H Qu, J P Lin. Laser-clad Inconel 625 coatings on Q245R structure steel: microstructure, wear and corrosion resistance. npj Materials Degradation, 2022 6, 37.

10. W Y Gui, Y H Qu, Y F Liang, Yanli Wang, Hui Zhang, Benli Luan, J P Lin. High efficiency hierarchical porous composite microfiltration membrane for high-temperature particulate matter capturing. npj Materials Degradation, 2021, 5(1): 1.

1. TiAl porous alloy with oxide film, preparation method and application thereof. Authorization Announcement Number: CN114182318B.

2. The invention relates to a microfiltration membrane, a preparation method and application thereof. Authorization Announcement Number: CN111531174B.

1. 2024 Advanced Light Metal Alloy Material Industry Development Forum Young Talent Award;

2. "Youth Innovation Beijing" 2023 Challenge Cup excellent instructor

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026